- Model RU (Integrated Inner/Outer Ring Type)

- Model RB (Separable Outer Ring Type for Inner Ring Rotation)

- Model RE (Two-piece Inner Ring Type for Outer Ring Rotation)

- Model RAU (Integrated Inner/Outer Ring Type)

- Model RA (Separable Outer Ring Type for Inner Ring Rotation)

- Model RA-C (Single-Split Type)

- Model RBU/CRBH (Inner and outer ring integrated type)

- Model CSF/CSG (Cup-type harmonic special bearing)

- Model SHF/SHG (Cap-type harmonic special bearing)

- Model SHD mini (Micro-type harmonic special bearing)

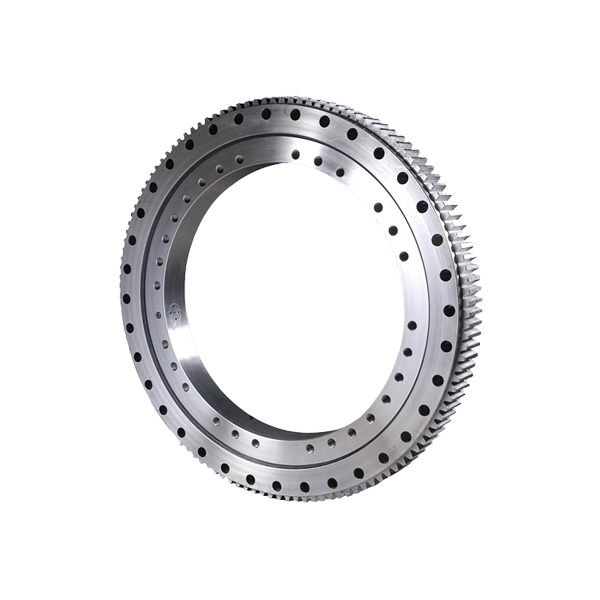

- HXSI series Crossed roller slewing bearing with internal gear teeth

- HXSU series Crossed roller slewing bearing

- HVSA Series Four-point contact ball slewing bearing with external gear teeth

- HVSI series Four-point contact ball slewing bearing with internal gear teeth

- HVSU Series Four-point contact ball slewing bearing

- HXSU08 series Crossed roller slewing bearing

- HXU Series Crossed Roller Slewing Bearing

- HXSA series Crossed roller slewing bearing with external gear teeth

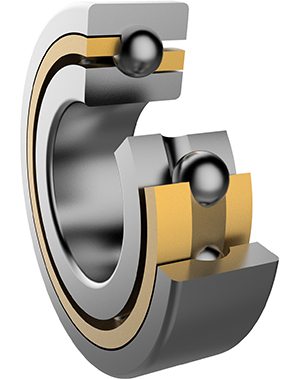

Explore the features of crossed roller bearings: More possibilities for your device !

In recent years, with the continuous improvement of the precision requirements of manufacturing technology in the machinery industry, more and more customers have turned to cross roller bearings to replace the bearings on the original precision equipment. This trend has led to an increasing popularity of crossed roller bearings in the market.

Cross roller bearings have a unique structure, the rollers are vertically arranged and cross each other at 90° degrees, with shims or separators between them to prevent tilting, friction or locking, effectively reducing rotational torque. Moreover, they can simultaneously withstand radial, thrust and moment loads from any direction, reducing bearing deformation and deflection during reloading.

As with the RB series, the internal structure of the crossed roller bearing enables high-precision rotational movement even with preload.

The rollers are arranged vertically and horizontally at 90°, and gaskets or spacers are installed between the rollers to prevent unilateral contact or locking of the rollers.